Mechanical Design

Our mechanical design team is used to being highly adaptable and innovative. We have found our broad design experience has allowed us to utilize knowledge gained in different industries and introduce new techniques in totally unrelated sectors. Clients benefit from the rapid introduction of this knowledge to improve products or processes and develop increased gains from their design investment.

CAD Design

-

We provide 2D and 3D mechanical CAD services catering to the specific drawing needs of mechanical engineers, fabricators, production engineers, and manufacturers. Benengg can help you in all stages of CAD design for your mechanical product. We can conceptualize the product and prepare it for manufacturing and test. We provide you with every possible capabilities and processes you need to develop manufacture your future mechanical products

Our CAD Services

- CAD Conversion

- CAD Drawings

- CAD Drafting

- CAD Designing

- 2D Draughting

- 3D modeling

- AutoCAD Consulting

CAM Design

-

Computer-aided manufacturing (CAM) is the use of computer software to control machine tools and related machinery in the manufacturing of workpieces. Using CAM our primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, CAM has advantage which uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption.

Our CAM Services

- NC Tool Path Generation

- Post Processors

- Tool and die design

- Mold Design

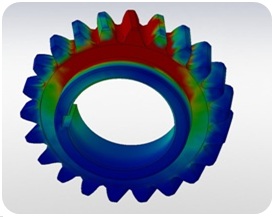

CAE Testing

-

CAE tools are being used, to analyze the robustness and performance of components and assemblies. The term encompasses simulation, validation, and optimization of products and manufacturing tools. In the future, CAE systems also act as providers of information to help support design teams in decision making.

CAE Functionality

- Stress analysis on components and assemblies using FEA (Finite Element Analysis)

- Thermal and fluid flow analysis Computational fluid dynamics (CFD)

- Mechanical event simulation (MES)

- Analysis tools for process simulation for operations such as casting, molding, and die press forming

- Optimization of the product or process